メニュー

JP | JPY

-

-

-

- Challenges and Chances: A Review of the 1st Stem Cell Community Day

- Summertime, and the Livin’ Is Easy…

- Follow-on-Biologics – More than Simple Generics

- Bacteria Versus Body Cells: A 1:1 Tie

- Behind the Crime Scene: How Biological Traces Can Help to Convict Offenders

- Every 3 Seconds Someone in the World Is Affected by Alzheimer's

- HIV – It’s Still Not Under Control…

- How Many Will Be Convicted This Time?

- Malaria – the Battle is Not Lost

- Physicians on Standby: The Annual Flu Season Can Be Serious

- At the Forefront in Fighting Cancer

- Molecular Motors: Think Small and yet Smaller Again…

- Liquid Biopsy: Novel Methods May Ease Cancer Detection and Therapy

- They Are Invisible, Sneaky and Disgusting – But Today It’s Their Special Day!

- How Many Cells Are in Your Body? Probably More Than You Think!

- What You Need to Know about Antibiotic Resistance – Findings, Facts and Good Intentions

- Why Do Old Men Have Big Ears?

- The Condemned Live Longer: A Potential Paradigm Shift in Genetics

- From Research to Commerce

- Chronobiology – How the Cold Seasons Influence Our Biorhythms

- Taskforce Microbots: Targeted Treatment from Inside the Body

- Eyes on Cancer Therapy

-

-

-

-

- Challenges and Chances: A Review of the 1st Stem Cell Community Day

- Summertime, and the Livin’ Is Easy…

- Follow-on-Biologics – More than Simple Generics

- Bacteria Versus Body Cells: A 1:1 Tie

- Behind the Crime Scene: How Biological Traces Can Help to Convict Offenders

- Every 3 Seconds Someone in the World Is Affected by Alzheimer's

- HIV – It’s Still Not Under Control…

- How Many Will Be Convicted This Time?

- Malaria – the Battle is Not Lost

- Physicians on Standby: The Annual Flu Season Can Be Serious

- At the Forefront in Fighting Cancer

- Molecular Motors: Think Small and yet Smaller Again…

- Liquid Biopsy: Novel Methods May Ease Cancer Detection and Therapy

- They Are Invisible, Sneaky and Disgusting – But Today It’s Their Special Day!

- How Many Cells Are in Your Body? Probably More Than You Think!

- What You Need to Know about Antibiotic Resistance – Findings, Facts and Good Intentions

- Why Do Old Men Have Big Ears?

- The Condemned Live Longer: A Potential Paradigm Shift in Genetics

- From Research to Commerce

- Chronobiology – How the Cold Seasons Influence Our Biorhythms

- Taskforce Microbots: Targeted Treatment from Inside the Body

- Eyes on Cancer Therapy

-

JP | JPY

Sorry, we couldn't find anything on our website containing your search term.

- What is a Bioreactor?

GMP info

Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

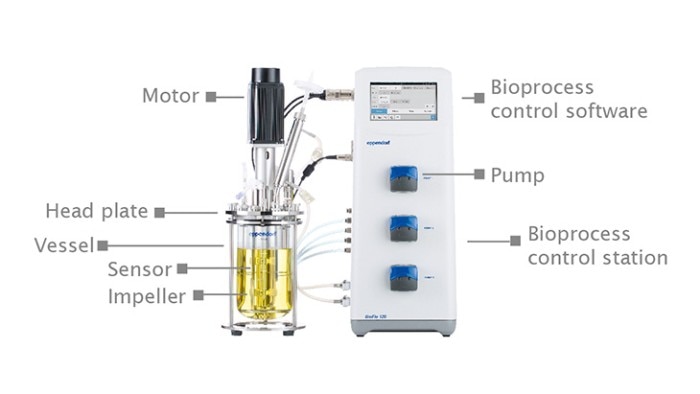

What is a Bioreactor?

- Sensors: These monitor key process parameters, including pH, dissolved oxygen and temperature continuously in real-time. Various types of sensors can be integrated into bioreactors.

- Control software: Based on sensor readings, the software calculates the adjustments to the system that are required to maintain parameter levels within their specified setpoint.

- Actuators: Regulated by the control software, actuators can be pumps, valves, or motors, that adjust the parameter back to its specified setpoint.

What are typical application areas for bioreactors?

Bioreactors are typically used in life science and pharma field, for food and feed applicatons, and bio-based chemicals production. Find out more about the use of bioreactors in the different application areas.

もっと読む

What you need to know before investing in a bioprocessing space in your lab:

There are important considerations to make when purchasing your first bioreactor. Get to know about the necessary lab infrastructure and about useful additional equipment like incubators and analyzers.

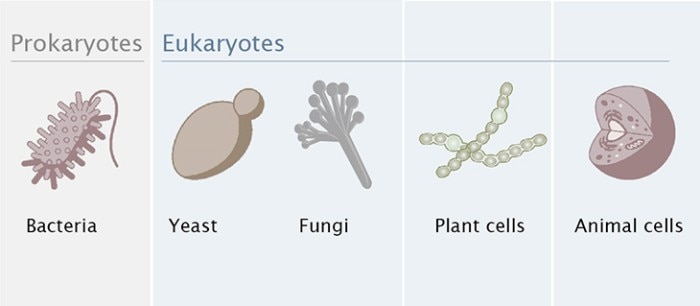

Which cell types can be cultured in bioreactors?

A broad range of cell types can be cultured in bioreactors, including:

- Mammalian cells , including stem cells

- Insect cells

- Bacteria

- Yeast and filamentous fungi

- Plant cells

Life science and pharma

Bioreactors are an especially powerful resource in the biopharmaceutical industry. Various cell types, including those from mammals, insects, microbes and stem cells are frequently used in bioreactors for the production of therapeutic compounds to improve disease diagnosis and treatment. Bioreactors are used for the development and production of biopharmaceuticals, including:

- Cells for cell therapy and drug discovery applications

- Viral vectors

- Monoclonal antibodies and other therapeutic proteins, peptides, hormones and enzymes

- Exosomes

- Vaccines

もっと読む

Food and feed

Furthermore, bioreactors are traditionally used in the food and feed industry for microbial fermentation to produce food, food additives, and beverages, including but not limited to:

The production of cultured n meat is an up-and-coming use of stem cell cultures in bioreactors.

- Beer, wine

- Dairy products

- Amino acids, vitamins, and flavors

The production of cultured n meat is an up-and-coming use of stem cell cultures in bioreactors.

もっと読む

Chemicals

Bioreactors are also used in the chemicals industry to produce

- Biofuels

- Platform chemicals

- Biopolymers

もっと読む

What is a bioreactor?

Bioreactors are vessels used to culture cells or microorganisms under tightly controlled conditions to provide optimal productivity, efficiency, and product quality. These vessels can be used to culture various types of animal and human cells. However, they’re also commonly used for the fermentation of microbes such as bacteria and yeast. Scientists who cultivate bacteria, yeast, or other fungi often use the term fermentor.

Bioreactors are useful for a wide range of applications at various scales of production. Continue reading to find out how the use of bioreactors can optimize your cell or microbial culture. Learn about the different components, cell types and applications suitable for bioreactor systems and receive expert advice on how to get started.

Bioreactors are useful for a wide range of applications at various scales of production. Continue reading to find out how the use of bioreactors can optimize your cell or microbial culture. Learn about the different components, cell types and applications suitable for bioreactor systems and receive expert advice on how to get started.

もっと読む

Produce large quantities of cells

Stirred-tank bioreactors are scalable, meaning they allow increasing the size of the cultivation vessel instead of the number of vessels, so that the work and space requirements stay manageable. To compare, stirred-tank bioreactors can have working volumes of thousands of liters, whereas culture flasks and dishes are usually not bigger than a few liters. Furthermore, bioreactors facilitate to automatically adjust potentially growth-limiting parameters, like the oxygen concentration in the culture medium or the concentration of nutrients, and therefore support high cell densities.

もっと読む

Decrease batch-to-batch variability

In bioreactors, critical process parameters, like pH, temperature, and dissolved oxygen can be continuously monitored in real-time using sensors and controlled at a setpoint. This is different from cultures in shakers or incubators, where often only the temperature is controlled. This helps increasing the reproducibility of culture growth, product formation, product characteristics, and more. Here you find more information about how bioprocess monitoring and control works.

もっと読む

Find the best culture conditions

By using small, parallel bioprocess systems several bioprocesses can be run at the same time. This is a time-saving way to systematically analyze the influence of several parameters on the culture outcome.

もっと読む

Shakers/incubators and bioreactors

If you are using bioreactors, you will probably use a shaker or incubator as well for early research and process development and inoculum preparation. This means, it depends on the application and the workflow stage, which cultivation system is the better choice.

- Get an overview on the strengths and weaknesses of shakers/incubators and bioreactors and at which workflow step the one or the other is particularly useful. Read more!

- Interested in an example? Read, how one of our customers optimized protein production in E. coli. Shake flasks were used at the beginning to optimize a range of process parameters. Subsequently, bioreactors have enabled a significant increase in productivity. Download case study!